Key Takeaways

- Concrete block making machines automate the production of masonry units, providing consistent quality, speed, and efficiency for construction projects.

- There are three main types: manual, semi-automatic, and fully automatic, each catering to different production capacities and automation needs.

- Key components include mixing and batching systems, molding machinery, conveyor and feeding systems, hydraulic presses, vibration tables, and digital control panels.

- Benefits include high productivity, reduced labor and material costs, consistent block quality, versatility in block types, and scalability for various project sizes.

- Concrete block making machines are ideal for a wide range of construction applications, from residential to commercial and municipal projects.

- When choosing a machine, consider factors such as automation level, production capacity, block types produced, durability, cost, maintenance, and portability.

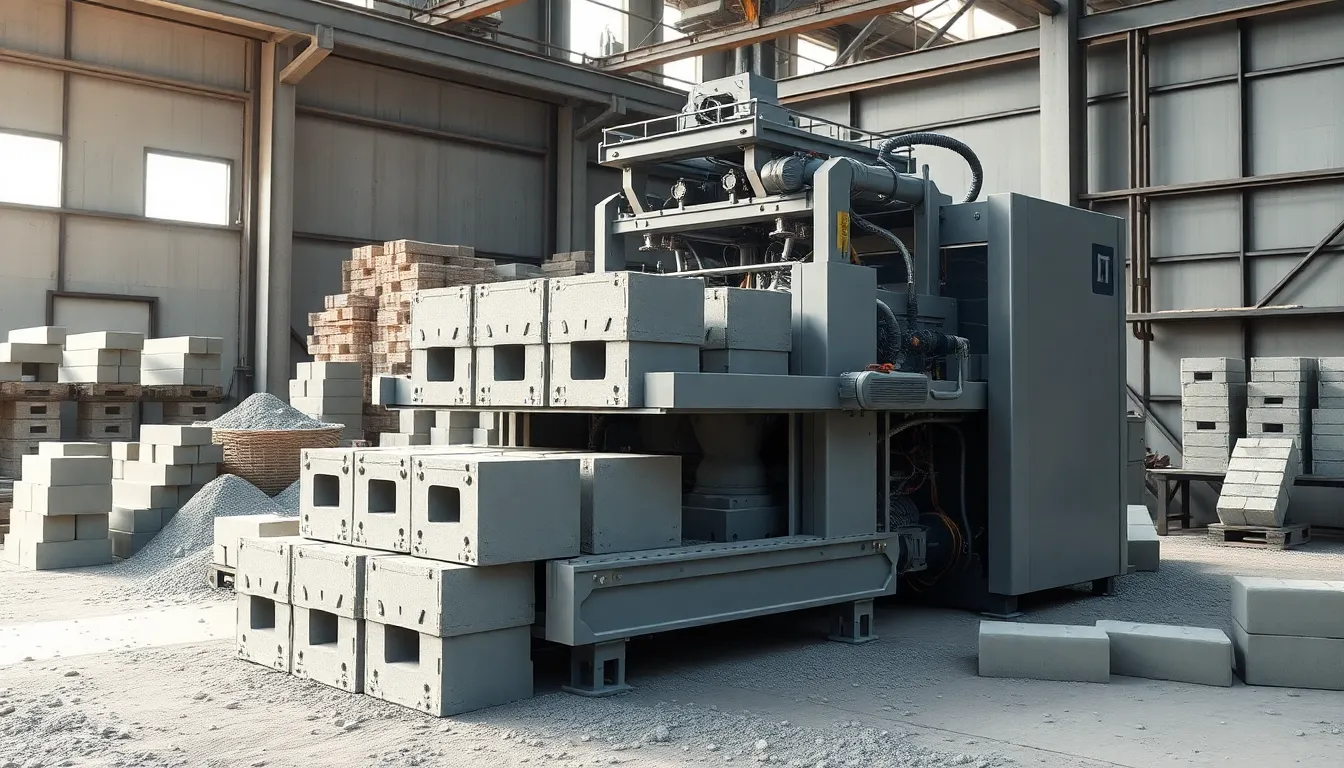

A concrete block making machine automates the production of uniform masonry units from a cement aggregate mix, transforming raw materials including cement, sand, water, and stone into sturdy concrete blocks used for walls, pavements, and other construction structures. These machines come in three main types – manual, semi-automatic, and fully automatic – with production capacities ranging from under 3,600 blocks per 8-hour shift for manual models to up to 14,400 blocks for fully automatic systems. Leading manufacturers like Lontto offer Concrete block making machine solutions that integrate key components including mixing systems, hydraulic presses, vibration tables, and digital control panels to deliver consistent quality, reduced labour costs, and scalable production for residential, commercial, and municipal construction projects.

Understanding What Is a Concrete Block Making Machine

A concrete block making machine automates the formation of uniform masonry units from a cement aggregate mix. Operators load raw materials including cement, sand, water, and stone into the designated hopper. The machine then mixes the components in controlled ratios and compresses them in heavy-duty molds. Hydraulic pressure or vibration solidifies the blocks, forming shapes such as hollow blocks, solid bricks, or pavers based on mold specifications.

Production output ranges from 3,600 to 14,400 blocks per 8-hour shift, depending on machine capacity. Lontto, a leading manufacturer with operations in Chicago, supplies machines configured for small-scale sites and large commercial plants. High-efficiency automatic models integrate a PLC control system, which reduces labor and improves block consistency. Semi-automatic and manual models, also offered by Lontto, suit remote projects or budget-focused operations.

Lontto machines use robust steel parts for higher wear resistance and longer service life under harsh conditions. Lontto’s technical support in the US supports customers with setup, training, and spare parts availability. Block making machines, such as Lontto’s, enable construction companies to maintain tight schedules and uniform structural results, whether for local building projects or industrial-scale developments.

Main Types of Concrete Block Making Machines

Concrete block making machines fall into three main categories based on their automation and production scale. These machine types suit different business needs, output targets, and budgets across the construction equipment market.

Manual Concrete Block Making Machines

Manual concrete block making machines operate entirely by hand. Operators load cement, sand, aggregate, and water, then mix, fill molds, and demold blocks manually. Average output for manual models stays under 3,600 blocks per 8-hour shift, making them suitable for startups, rural sites, and small commercial projects. Manual machines from Lontto in Chicago use solid steel for durability and low maintenance. Hand-operated block makers provide flexibility for producing standard rectangular blocks or hollow units but require higher labor input per block.

Semi-Automatic Concrete Block Making Machines

Semi-automatic concrete block making machines blend mechanized and manual operation steps. Core stages, such as mixing or pressing, use electric motors or hydraulic systems, while loading molds and collecting blocks might need manual handling. Output typically ranges from 3,600 to 7,200 blocks per 8-hour shift. Lontto semi-automatic machines suit mid-sized contractors aiming for steady production volumes with moderate labor force. Standard models support mold options like single or double hoppers, producing items such as paving stones or hollow blocks with improved uniformity and strength.

Fully Automatic Concrete Block Making Machines

Fully automatic concrete block making machines handle the full process from batching to stacking with integrated automation. Operators input material recipes; the system manages mixing, feeding, molding, vibration or hydraulics, and block ejection. Leading brands, including Lontto in Chicago, offer automatic lines capable of 7,200 to 14,400 blocks per 8-hour shift. Industrial operations and large-scale producers use these machines for high-speed runs and consistent quality. Features like PLC control, touch screen panels, and automatic pallet feeding reduce labor and maintain precise quality for block types such as interlocking pavers and architectural blocks.

Key Components and How They Work

A concrete block making machine integrates a sequence of critical systems that shape, densify, and finish blocks to meet structural requirements. Each system within the machine plays a specialized role in the manufacturing process, directly affecting the final quality and yield, as seen in Lontto’s plant operations serving Chicago and North American construction markets.

- Mixing and Batching System

This component measures cement, sand, aggregates, and additives according to preset ratios. Automated controls in Lontto machines ensure every batch delivers consistent density and strength, critical for meeting ASTM block standards in the US.

- Block Forming Machinery (Molding System)

Operators load wet concrete into steel molds, where hydraulic or mechanical presses shape the material. The Lontto molding system uses both pressure and vibration to achieve block density without air gaps, producing standard hollow, solid, or paver blocks on each cycle.

- Conveyor Belt and Feeding System

Conveyor belts transport mixed concrete to the molds for uninterrupted workflow. Lontto’s automated feeding designs minimize material loss and help maintain high-cycle output in busy Chicago precast block yards.

- Hydraulic Unit/Compression Mechanism

Hydraulic cylinders apply precise pressure during forming, guaranteeing that each block meets the compressive strength benchmarks. Lontto machines rated for up to 14,400 blocks per 8-hour shift in industrial operations depend on this system for fast, uniform molding.

- Vibrating Table/Compaction System

Integrated high-frequency vibrators compact concrete inside the molds. This compaction eliminates air voids, ensuring blocks from Lontto machines match Chicago Department of Buildings durability codes.

- Control System

Digital or PLC-based control systems manage batching, pressure, vibration, and timing. Lontto provides US-based support for these control panels, enabling contractors to adjust recipes or operating cycles for best results with regional aggregates.

- Curing and Hardening Equipment

Blocks exit molds onto racks and remain in controlled environments for initial curing. Lontto machines allow for steam or moisture curing processes to comply with both fast turnaround requirements and quality standards.

Connecting these components, the overall workflow in Lontto equipment combines precision measurement, thorough mixing, powerful molding, dense compaction, and controlled curing—delivering reliable, scalable block production for commercial and municipal projects in the Midwest.

Benefits of Using a Concrete Block Making Machine

A concrete block making machine delivers measurable productivity gains and cost control on construction sites. Lontto equipment in Chicago supports these advantages by supplying machines built for compressed concrete block output and industry-ready quality.

- Efficiency and Speed

Machines like Lontto’s automatic line produce up to 14,400 blocks in one 8-hour shift, which enables contractors to meet schedules for large projects without manual delays.

- Cost-Effectiveness

Block making machines reduce labor demand, automate material mixing and compression, and limit wastage. Lontto operators in the Midwest report labor cost savings and lower rejected block rates due to automation.

- Quality and Consistency

Machines apply uniform hydraulic and vibratory force, producing blocks that meet ASTM standards for structural integrity. Lontto’s designs use durable steel and strict control systems for repeatable results.

- Versatility

Adjustable mold settings allow the machine to manufacture multiple block sizes and profiles on demand. Lontto supplies molds to fit regional building codes and customer project requirements.

- Supports Local Production

Onsite block manufacturing reduces reliance on third-party suppliers and cuts transportation costs. Projects in Chicago using Lontto machines gain direct control of their block inventory.

- Scalability

Automatic machines handle thousands of blocks per shift for high-volume output, while compact mobile machines serve smaller sites. Lontto product ranges match contractors’ expansion or project-specific needs.

Block makers such as Lontto enable reliable, industry-compliant concrete block production in both urban and suburban settings, serving both small contractors and industrial operations across the Midwest.

Common Applications in Construction

Concrete block making machines supply key building materials for construction across residential, commercial, and municipal projects. Contractors apply hollow, solid, and interlocking concrete blocks in walls, load-bearing structures, and foundations of single-family homes, apartments, and townhouses. Typical installations in Chicago and the Midwest use Lontto machines to supply blocks meeting ASTM C90 or C129 standards for strength and weather resistance.

Office buildings, shopping malls, and business parks use blocks produced by automated machines for both exterior walls and partitioning in interior layouts. High-rise developments—hotels, hospitals, and university dormitories—rely on structural-grade blocks made by Lontto automatic models to support multi-story frameworks and meet tight timelines. Affordable housing projects for city housing authorities and private developers use high-output units to manufacture blocks at scale, keeping overall construction costs below conventional cast-in-place concrete methods.

Municipal projects benefit from specialized molds to create kerbstones, pavers, retaining wall units, and fly ash bricks. Sidewalks, parking areas, and street edging in urban infrastructure developments use up to 14,400 paver blocks per shift with a fully automatic line. Lontto’s modular machines in Chicago align with these applications, supporting local contractors with technical support for mold changes and mass production.

Factors to Consider When Choosing a Concrete Block Making Machine

Type of Machine

Select a type based on project scale and workflow. Fully automatic machines deliver 8,000–20,000+ blocks daily for high-volume operations, while semi-automatic, manual, hydraulic, mobile, and egg-laying units suit smaller or flexible projects. Lontto in Chicago supplies all major machine classes for residential, commercial, and municipal applications.

Production Capacity

Check block output per shift. Large-scale manufacturing benefits from high-capacity models like Lontto’s automatic series, producing up to 14,400 blocks per 8-hour shift. Manual or semi-automatic options meet demand for smaller projects up to 7,200 blocks per shift.

Automation Level

Choose automation to match labor availability and budget. Fully automatic machines reduce labor and increase consistency, while semi-automatic or manual machines require hands-on operation. Lontto’s PLC-controlled automatics optimize efficiency for industrial workflows.

Block Types Produced

Identify machines by block design output. Models make hollow blocks, solid blocks, interlocking blocks, and pavers. Lontto offers solutions for ASTM-standard hollow, solid, and paving blocks for Midwest developments.

Quality and Durability

Evaluate compression methods. Hydraulic machines yield denser, high-strength blocks needed for structural walls and weather-resistant pavers. Lontto uses robust steel frames and hydraulic systems for long service life in Chicago projects.

Cost and Maintenance

Account for purchase price, maintenance, and spare parts access. Lontto machines include local technical support and parts, ensuring minimal downtime and strong ROI for US clients.

Portability

Select mobile or egg-laying machines for on-site block production. These are practical for remote sites where transporting finished blocks increases costs. Lontto’s portable machines support direct placement on Midwest construction sites.

About Lontto

Lontto, located in Chicago, IL, is a leading manufacturer specializing in block and brick making machines.

Under the leadership of CEO Chao Zhang, Lontto offers a diverse range of products including concrete block machines, mobile block making machines, and compressed earth block machines. They also provide essential services such as installation and training to ensure the efficient operation of their equipment. Lontto is committed to delivering reliable and high-quality machinery solutions for clients in the construction and manufacturing industries.

Contact:

Chao Zhang, CEO

Phone: 708 260 8300

Email: [email protected]

Website: www.block-machine.net

Location:

4992 S Austin Ave, Chicago, IL 60638, USA

Frequently Asked Questions

What is a concrete block making machine?

A concrete block making machine automates the production of concrete blocks from a mix of cement, sand, stone, and water. It shapes and compresses the mixture into uniform blocks, ensuring consistent quality and higher productivity compared to manual methods.

How does a concrete block making machine improve construction efficiency?

These machines speed up the block production process and ensure uniformity in each block. This automation helps construction teams meet deadlines, reduce labor costs, and maintain high standards for building durability.

What types of concrete block making machines are available?

There are manual, semi-automatic, and fully automatic machines. Manual machines are labor-intensive and best for small-scale projects. Semi-automatic machines combine manual and automation, while fully automatic machines suit industrial operations needing the highest output.

What are the main components of a concrete block making machine?

Key components include the mixing and batching system, block forming machinery, conveyor belt system, hydraulic unit, vibrating table, control system, and curing equipment. Each part contributes to efficient and quality block production.

How many blocks can a concrete block making machine produce per shift?

Production depends on the machine type. Manual machines produce under 3,600 blocks per 8-hour shift, semi-automatic machines yield 3,600–7,200, while fully automatic ones can make 7,200–14,400 blocks per shift.

Why choose Lontto concrete block making machines?

Lontto machines are known for durability, high output, and reliable technical support. They offer a range of models to suit different project sizes, budgets, and automation needs, making them a preferred choice in the Midwest.

What are the benefits of using a concrete block making machine?

Benefits include increased productivity, controlled labor costs, reduced material waste, consistent block quality, customizable block sizes, and lower transportation expenses thanks to onsite manufacturing.

What types of blocks can these machines produce?

They can produce hollow, solid, and interlocking concrete blocks, as well as specialized shapes like kerbstones, pavers, and retaining wall units, depending on the molds used.

Are these machines suitable for both small and large projects?

Yes, there are manual and semi-automatic machines for small and mid-sized projects, while fully automatic machines are designed for large-scale and industrial applications.

What standards do the blocks produced meet?

Blocks made with modern machines, like those from Lontto, usually comply with ASTM C90 or C129 standards for strength, durability, and weather resistance, suitable for residential, commercial, and municipal uses.

How do I choose the right concrete block making machine?

Consider your project scale, desired automation level, production capacity, block types, equipment durability, cost, and technical support when selecting a machine. Matching these factors ensures you get the best machine for your needs.